Quality first, service with heart, quality assurance, reputation first

The company uses system operation (RRP) software management, timing quotes, bar code tracking, clear division of labor, and the overall production process can be monitored. The process section can be tracked. Clearly fulfill customer needs.

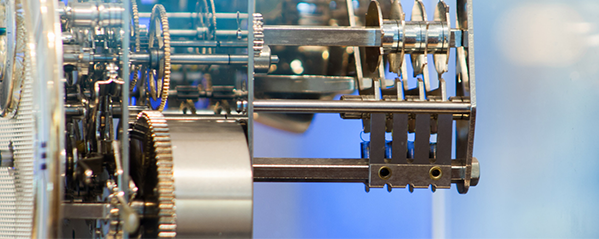

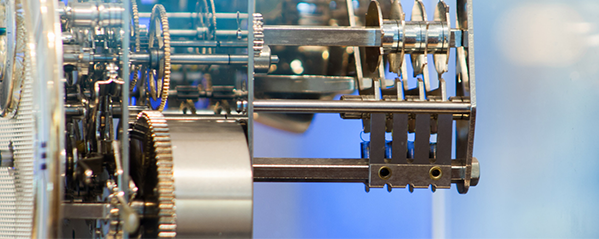

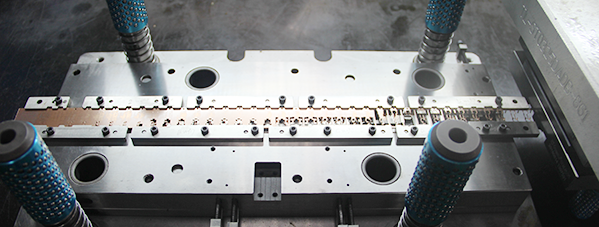

Ultra-precision equipment such as Japan, Germany, Switzerland, etc., is connected with precision (EROWA) tools to complete each precision machining process.

The company uses materials such as Datong in Japan, Hitachi in Japan, and a hundred wins in Switzerland. It adopts advanced vacuum treatment, secondary tempering, ultra-deep cooling and ultra-cold treatment.

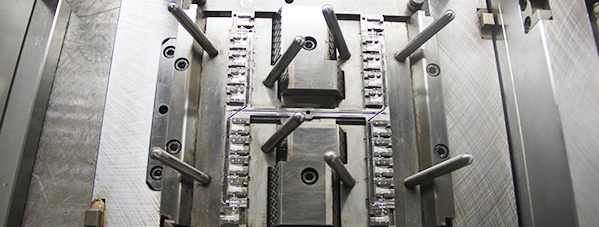

After years of technical accumulation and breakthrough, ultra-mirror processing (Ra0.13) ultra-fine edge clearance (0.007mm) flatness (0.001mm), slot width (0.009mm) depth (2.0mm), etc., the processing environment is maintained at a constant temperature .