Difficulty, high precision, fine processing, quality assurance

From precision to classic, more than 0.001mm distance

Provide products that exceed customer expectations, strive for excellence, and strive for excellence

high productivity

Quality assurance

High processing accuracy

Customized according to demand

tracking service

Quality first, service with heart, quality assurance, reputation first

The company uses system operation (RRP) software management, timing quotes, bar code tracking, clear division of labor, and the overall production process can be monitored. The process section can be tracked. Clearly fulfill customer needs.

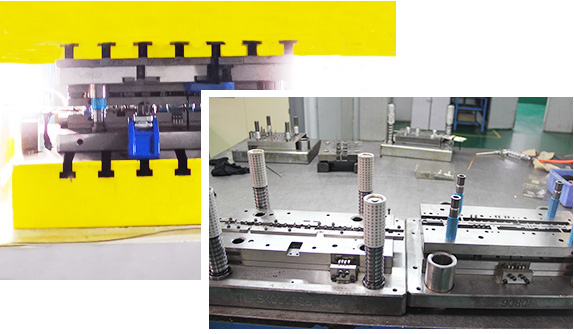

Ultra-precision equipment such as Japan, Germany, Switzerland, etc., is connected with precision (EROWA) tools to complete each precision machining process.

The company uses materials such as Datong in Japan, Hitachi in Japan, and a hundred wins in Switzerland. It adopts advanced vacuum treatment, secondary tempering, ultra-deep cooling and ultra-cold treatment.

After years of technical accumulation and breakthrough, ultra-mirror processing (Ra0.13) ultra-fine edge clearance (0.007mm) flatness (0.001mm), slot width (0.009mm) depth (2.0mm), etc., the processing environment is maintained at a constant temperature .

Provide systematic solutions for customer molds

Dongguan Taiwei Electronics Co., Ltd. is located in Humen, Dongguan, a famous historical town. It was established in 1997. It focuses on the design, processing and production of precision earphone sockets, SIM card holders, TYPE-C, Micro USB and other connector products. produce. Plastic mold department introduction: In 2008, the high quality requirements of the earphone socket product ST0258 development, the company's mold design, processing, production level has reached a new level. In 2010, the company began to standardize plastic molds. In the same year, it established the standard of 10-hole shared mold base for earphone sockets. After years of continuous study and exploration, it has established earphone sockets...

see more+ Taiwei and Simei pay tribute to the Mid-Autumn Festival for the elderly

Taiwei and Simei pay tribute to the Mid-Autumn Festival for the elderly

Mold heat treatment deformation is one of the main defects of the mold processing process. For some sophisticated molds, they are often scrapped due to heat treatment deformation, so control sophisticated molds...